Educational and Scientific Centers

On October 12, 2012, the grand opening of “Educational and scientific bread center” took place within the framework of the International scientific and practical conference “Innovative development of the food, light industry and hospitality industry”. The opening ceremony was attended by guests from 12 countries of leading universities and research centers of Kazakhstan, Great Britain, the Czech Republic, Bulgaria, Spain, Italy, Russia, Ukraine, Belarus, the Republic of Korea, Kyrgyzstan and Uzbekistan.

The activity of “Educational and scientific bread center” is one of the largest achievements and opens up wide opportunities for the introduction of scientific developments of university into production, holding seminars and master classes with representatives of leading companies in Kazakhstan. Over the past five years, the food industry enterprises of the republic have been offered about ten innovative projects to improve the technological properties of leguminous crops, the quality of bread, five of which have been introduced into production. Among them are the improved aspiration system in “Altyn Diirmen” JSC, the ion-zone technology for processing grain and dough in “KazBestGray” LLP, the technology for developing new types of wheat bread in “KHBK Aksay” LLP.

In the “Educational and scientific bread center” there are installed: a rotary oven, a proofing chamber, a spiral dough mixer, a dough divider, a divider-rounder made in Italy.

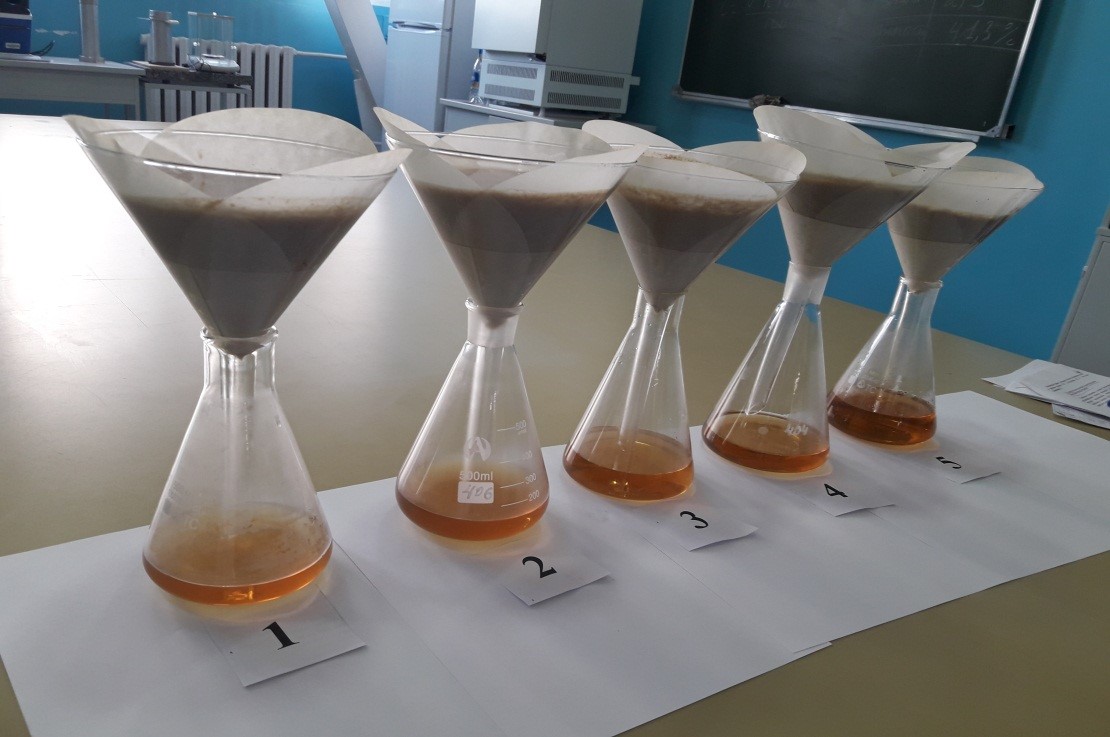

In the educational and scientific center, laboratory classes are held on the discipline “Technology of bakery production”, “Technology of products of increased nutritional value”. In addition, master’s students and doctoral students conduct research on dissertations.

"Educational and scientific bread center" Conducting laboratory classes in the discipline "Technology of products of increased nutritional value"

.jpg)

.jpg)

.jpg)

On October 30, 2015, the grand opening of “Educational and scientific pasta center” was held, the opening ceremony of which was attended by guests from leading universities and research centers of Kazakhstan, Russia, Ukraine, administration, teaching staff of “ATU” JSC, including teachers of “Technology of bread products and processing industries” department, students, as well as representatives of advanced enterprises of the food industry of Kazakhstan. The guests of honor highly appreciated the importance of “Educational and scientific pasta center” as one of the most important conditions for obtaining high-quality education, studying innovative technologies, and developing functional products for the population.

In “Educational and scientific pasta center”, not only laboratory work for bachelors is carried out, but also the introduction of scientific developments of young scientists of university into production is carried out. Bachelors, master’s students and doctoral students conduct their research work. In addition, seminars and master classes are held in the educational and scientific center. The center is equipped with a semi-automatic mini-line for the production of short-cut pasta (horns, vermicelli, noodles) from soft and durum wheat flour (high-grade baking flour with 26-32 % gluten). The mini-line consists of a pasta press of the PMI-02 brand and two drying cabinets of the SHS-1 brand. Additional equipment of the line is the U-01 semi-automatic filling and packaging machine and the MP-03 flour sifter.

The two-bunker PMI-02 pasta press is designed for kneading dough, forming, cutting and pre-drying pasta made from flour of any wheat varieties: hard and soft, fine and coarse grinding, semolina and their mixtures. Drying cabinet SHS-1 is designed for drying pasta from the initial humidity of 36.2 % to the residual humidity of 19 %. Drying of pasta is carried out by forcibly blowing them with hot air. The drying cabinet operates in semi-automatic mode. The temperature mode is maintained automatically.

Using of educational and scientific center in the educational process is one of the most important conditions for obtaining high-quality education, studying innovative technologies, and developing new products. Conducting laboratory classes in the “Educational and scientific pasta center”, where the conditions are as close as possible to the production, allows students to learn the material as much as possible and qualitatively.

Production of pasta products

Conducting scientific and research works of master’s students

Scientific and research work of the doctoral student Umirzakova G.A.

The doctoral student Umirzakova G. A. conducted research at the “Educational and scientific pasta center” on the topic of the dissertation on the international project funded by the Ministry of Education and Science of the Republic of Kazakhstan STP “International scientific and technical programs and projects for 2013-2015” on the topic “Development of technology for functional macaroni products for different groups of the population using raw materials of plant origin”

«The educational and scientific center of meat processing» was inaugurated at the Almaty Technological University on October 18, 2013 with the participation of foreign scientists and researchers from partner universities of «ATU» JSC.

The opening ceremony was attended by guests from leading universities and research centers of Kazakhstan, Russia, Ukraine, the administration and teaching staff of «ATU» JSC, as well as teachers of the Department of «Technology food products», students, representatives of leading enterprises of the food industry in Kazakhstan. The honored guests highly appreciated the importance of the Educational and Scientific Center of Meat Processing as one of the most important conditions for obtaining high-quality education, studying innovative technologies, and developing functional products for the population.

The established «Educational and scientific center of meat processing» opens up great prospects for: introducing scientific developments of university scientists into production, conducting seminars and master classes. The center conducts laboratory and research works on the technology of meat production for students, master and PhD students.

Research work of students, undergraduates and doctoral students

The functioning of the «Educational and scientific center of meat processing» allows for the training of highly qualified specialists and the conduct of scientific research based on the integration of education, science, production and the best international experience for personnel and scientific and innovative support of the food industry of the Republic of Kazakhstan.

The center is equipped with the latest advances in sausage and meat production. A full cycle of meat processing has been organized: the processes of cutting, deboning, trimming, salting of raw materials, mincing, shaping, heat treatment and storage of finished sausages and meat products.

The center is equipped with the following equipment: heat chamber (UK-3 / 1M100), refrigerating chamber KHN-9, tabletop meat grinder LaMinerva AE-22, hydraulic syringe LaMinerva CE INS/32, tabletop meat mixer haMinerva C/E MM-30, cutter Talsa K15, injector manual, vacuum desktop massager Suhner VT-20, vacuum sealer, table clipper «Korund-clip» 1-25R, production tables, 2-section washing bath for washing raw materials, etc.

Technological line for the production of meat products

Achievements of the Department of «Technology food products»

The scientific developments of young scientists created in the center constantly participate in various competitions, exhibitions not only at the republican, but also at the international level. The products of master and PhD students are annually awarded with gold, silver and bronze medals, as well as certificates of honor at the Russian agro-industrial exhibition «Golden Autumn» (Russia, Moscow), at the International Exhibition «Dairy and Meat Industry», domestic exhibitions «Karaotkel», «Altyn Dastarkhan», «Kazakhstan Food Market», etc.

The research project «Development and implementation of innovative technologies for deep processing of milk of agricultural animals» was carried out (head — academician of the National Academy of Sciences of the Republic of Kazakhstan, doctor of chemical sciences, professor Kulazhanov K.S., President of «ATU» JSC) (customer of the Ministry of Education and Science of the RK) in 2012-2014 years at the Department of «Technology of food products» of the ATU with a financing volume of 60 million tenge, three stages of which received high indicators from experts, interim and final reports were successfully approved by the Ministry of Education and Science of the RK. Based on the results of the research work, 6 pre-standards of the RK were developed, approved and included in the register of the KTRM MID of the RK. The second research project «Development of innovative technology of semi-hard cheeses using new bacterial compositions and fillers» was carried out (head — academician of the Academy of agricultural sciences of the RK, d.t.s., prof. Alimardanova M.K.) (customer of the Ministry of education and science of the RK) in 2013-2015 years with a funding of 20 million tenge, three stages of which received high indicators from experts, interim and final reports were successfully approved by the Ministry of Education and Science of the RK. The normative document «Technological regulations for the production of semi-hard cheese «Almaty» was developed based on the results of research and development. Scientific work was completed with a high economic effect and practical implementation at food industry enterprises. Within the framework of these research projects, technological equipment for the production of dairy products was purchased, a project of the center was drawn up, installation and commissioning of technological equipment, the launch and trial production of dairy products were carried out, which was carried out by prof. Alimardanova M.K. of the Department of «Technology of food products».

The grand opening of the «Educational and scientific center of milk processing» took place within the framework of the ISPC and the III Forum, dedicated to the Day of the First President of the Republic of Kazakhstan on October 30, 2015 at the «ATU» JSC. The opening ceremony was attended by guests from leading universities and research centers of Kazakhstan, Russia and Ukraine.

Opening of the «Educational and scientific center of milk processing» (gen.director of «Smak LLP» Talasov E.T., project manager prof. Alimardanova M.K., head of the Department of Voronezh state university of engineering technologies, d.t.s., prof. Shakhov V.V.

«The educational and scientific center of milk processing» is designed to create fermented milk products, cottage cheese, cheeses and ice cream. It has 3 technological lines equipped with the following types of equipment: tanks for milk and fermented milk products, separator, Bertoli homogenizer, heater, filling machine, automatic capping gun, centrifugal pump, automated complex for cheese and cottage cheese, installation for mozzarella cheese, press for cheese, mini cheese dairy, mixer, freezer, washing tub, tables and shelves.

Technological line for the production of dairy products

To carry out analyzes to determine the quality of raw milk entering the center, a laboratory is provided in which laboratory installations are installed to determine titratable acidity, temperature, purity, thermal stability, a pH meter for analyzing the active acidity of raw materials, a Jenway device for biochemical analyzes, a thermostat, exhaust unit, scales, etc.

The scientists are working out the modes and methods for the production of new types of lactic acid products: yoghurts, cottage cheese, cheeses, ice cream of various assortments and recipes, including national dairy products, as well as laboratory and research work on the technology of milk and dairy products for students, master and PhD students at the «Educational and scientific center of milk processing».

Research work of students, master and PhD students

«The Educational and scientific center for the production of grain mixes» was established in 2016 through a commercialization project (contract № 217 dated October 14, 2016) with the aim of introducing the technology of domestic functional grain mixtures for the enrichment of bread products at grain processing enterprises in Kazakhstan.

In October 2016, the opening of the «Educational and scientific center for the production of grain mixtures» took place, the opening ceremony of which was attended by: guests from the leading universities and scientific centers of Kazakhstan, the administration and teaching staff of «ATU» JSC.

Scientists of the «Educational and scientific center for the production of grain mixtures» have worked out the technological modes and parameters of the production of grain mixtures in the following assortment on the acquired technological equipment: «Magnificent Seven», «Golden Mix», «Protein Mix», «Healing sprouts», «Omega 6».

Packaged grain mixtures

Also, scientists of JSC «ATU» — Kulazhanov T.K., Kizatova M.Zh., Pronina Yu.G., Nabieva Zh.S., Iztaev A.I., Gumarov B.S., Nurgozhina Zh.K. received a patent for invention № 33792 «Composition of grain mixtures for enrichment of bread products (options)», which was published on July 26, 2019, bulletin № 30.

«Educational and scientific center for the production of grain mixtures» opens up great prospects for: the development of new types of grain mixtures, the introduction of scientific developments of university scientists into production, and more. In the educational and scientific center, laboratory and research work is carried out on the technology of obtaining various grain mixtures for students, undergraduates and doctoral students.

The following devices and equipment are installed in the «Educational and scientific center for the production of grain mixtures»:

Filling machine

Washing machine

Drying cabinets

On October 23, 2019, the grand opening of the «Educational and scientific center for the production of animal feed» took place, the opening ceremony of which was attended by: guests from the leading universities and scientific centers of Kazakhstan, akim of the Auezov district of Almaty Sairan Sayfedenov, administration and teaching staff of «ATU» JSC.

«Educational and scientific center for the production of animal feed» is intended for: conducting practical training with students and scientific research undergraduates and doctoral students; performing research work by departments and research laboratories. In this center, the implementation of scientific developments of young scientists of the university into production is carried out, seminars and master classes are held.

«Educational and scientific center for the production of animal feed» opens up great prospects for: the development of new types of compound feed, the introduction of scientific developments of university scientists into production, and more. The educational and scientific center conducts laboratory and research work on the technology of feed production for students, undergraduates and doctoral students.

The following equipment is installed in the «Educational and scientific center for the production of animal feed»:

- AK-1000 compound feed unit with a capacity of 1 ton / hour, designed to develop pilot batches of loose compound feeds of various recipes with high quality grinding and mixing for different age groups and categories of animals, birds, fish. The unit includes: a flexible hose with a tip for pneumatic intake of grain and protein raw materials, a stone separator, a vibration separator, a crusher, a weighing batcher, a mixer, a receiving tray for feeding premixes and mineral raw materials;

- granulator MUZL180 with a capacity of 180-400 kg / h, designed for the production of granulated feed of various diameters and sizes from loose feed;

- feed extruder with a capacity of 100 kg / h, designed for the production of extruded feed;

- a line for the production of premixes, consisting of a laboratory crusher, electronic scales for weighing trace elements, an analytical balance for weighing a filler, three mixers for stage-by-stage mixing of trace elements with a filler with a gradual increase in the mass of filler to achieve maximum homogeneity of the mixture, as well as a sieve;

- a device for determining the crumbling of feed pellets and others.

The main devices and installations of the "Educational and scientific center for the production of animal feed"

Combined feed unit AK-1000

Granulator MUZL180

Fermenter

Device for determining crumbling of compound feed pellets

Universal grain peeler UGP – 1

Laboratory mixer for compound feed

Sifter for grain and compound feed

Premix production line

«Educational restaurant» is a form of organizing the educational process in the mode of a real-life enterprise, which makes it possible to implement practice-oriented training of students. One of the purposes of this educational technology is the development of professionally significant personal qualities of students: creativity and initiative, critical thinking, self-esteem, responsibility for decisions.

Educational technology is aimed at:

- bridging the gap between the theoretical disciplines of the professional cycle and industrial training, practice in production;

- erasing the contradictions between the competencies of a university graduate and the requests of employers, real production conditions;

- development of students’ creative abilities, independence and initiatives, their ability to find their place in the employment market.

The presence of its own «Educational restaurant» and «Educational and scientific center for the production of catering products» is the pride of the department. Training at the centers allows to acquire practical skills in food production. «Educational restaurant» for 35 seats is equipped with modern equipment necessary for the service sector.

«Educational restaurant»

The students consolidate the knowledge gained in theoretical lessons and develop psychological communication skills in a team in the «Educational and scientific center for the production of public catering products» and in the «Educational restaurant». Educational technology in the process of vocational education can be successfully implemented provided that future young specialists – catering technologists are able to successfully apply the acquired knowledge, skills and abilities in practice.

In order for future young specialists to develop the necessary competencies, they must:

- gain basic knowledge while studying interdisciplinary courses;

- use the acquired knowledge in theoretical studies and in production practice;

- apply knowledge and skills of work in public catering enterprises.

The basic principles of building the «Educational and scientific center for the production of public catering products» and «Educational restaurant»:

- «Educational and scientific center for the production of public catering products» and «Educational restaurant» — a certain type of activity aimed at full-fledged training of personnel for public catering enterprises – cafes and restaurants. The educational and scientific center has an isolated working space with the required number of workplaces;

- while working at the Educational and scientific center, each student has an independent work area, and the amount of work that must be completed in a certain period of time is also determined;

- each workplace is completed with the necessary equipment in accordance with production, sanitary and hygienic requirements and regulatory documentation;

- general management in the Educational and scientific center is carried out by teachers of special disciplines who provide training;

- students use the equipment, tools and devices of the Educational and scientific center in laboratory studies;

- students under the guidance of a teacher, in practical classes, work out, consolidate and improve the knowledge gained during the theoretical part of training. On the basis of the specialty standard, a list of actions (functions) that must be performed by students and a list of documents that confirm the performance of functions have been compiled.

Table setting in the «Educational restaurant»

The opening ceremony of the «Educational and scientific center for the production of public catering products»

The university has a unique educational and material base for the training of highly qualified specialists. It includes well-equipped workshops and laboratories.

Training and production centers are equipped with innovative equipment of a new generation, where students consolidate their theoretical knowledge and practice practical skills to improve professional skills.

To improve the professional level of students in the educational and production workshops, master classes and training seminars are held. Students are able and qualified to fulfill their skills in training and production workshops.

Laboratory classes on the discipline «Technology of public catering products»

The basis of the effective viability of any university is professional orientation among students of schools, professional colleges to form the personal qualities of applicants necessary for choosing a profession and achieving professional and social success.

In 2019, master classes for schoolchildren and college students of Almaty were held at the «Educational and scientific center for the production of public catering products».

On April 20, 2019, the «Department of technology of food products» organized a master class on the topic «The use of fresh edible flowers in the design of ready-made meals» for the invited schoolchildren and college students. The master class was held in the scientific laboratory «Technology of cooking food products» under the guidance of prof. A.M. Taeva, ass.prof. Sh.Y. Kenenbay, senior lecturer A.M. Kapbasova and the chef of the restaurant «TIAMO» Akbarov R.

Master classes as one of the tools when choosing a profession

During this master class, the use of fresh edible flowers in the design of modern cuisine was demonstrated, the students were involved in the work process, in which they showed great interest.

On November 20, 2019, a master class on the topic “Dishes of European cuisine” was held at the “Educational and scientific center for the production of public catering products”. The chef of the restaurant «Myata» Atmyshev Damir and the chef of the restaurant «Olovo» Kulakidi Pavel demonstrated the preparation of specialties of European cuisine.

A successful example of effective interaction between the university and industrial enterprises of Kazakhstan is «Scientific training center of fermentation products production» created on the basis of technopark of «ATU» JSC with the sponsorship of «Efes Kazakhstan» JSC IE.

«Efes Kazakhstan» supported both the renovation of the premises and the purchase of a unique experimental Micro-brewery type MB75 (Czech Republic) for beer preparation (mini-brewery) and auxiliary equipment.

Micro-brewery Micro-brewery type MB75

The brewing process of automatic laboratory microbrewery is mounted in a single frame. The productivity of the brewer is 8 hl of wort per cooking.

The monoblock of the cooking order includes:

– mash-mash vat;

– filter tank/wirpool;

– steam generator;

– wort cooler.

The next node, without which brewing is impossible, is the fermentation tanks.

Fermentation tanks are also mounted on a single frame and include:

– 4 CCT (cylindrical-conical tanks) with a capacity of 8 hl each, insulated, cooled, equipped with a temperature control system;

– glycol plant.

Thus, students have the opportunity to consolidate their knowledge by applying the latest brewing technologies: to prepare both ordinary beer and develop special varieties. This approach to training will allow graduates to approach their professional activities as ready-made specialists.

The main task of educational and scientific center is to involve students in practical experience, to arouse young people’s interest in new scientific knowledge that goes beyond the basic educational programs.

Professional technologies of the highest category of leading enterprises of Kazakhstan and foreign countries will conduct training workshops and seminars on the production of soft drinks for students.

The microbrewery is a key factor in driving innovation in Kazakhstan’s brewing industry. The practical work of students on this equipment will allow you to track all the processes of brewing production from the crushing of malt to the output of the final product.

Laboratory classes for students of the specialty 5B072800 – «Technology of processing industries» of the educational trajectory «Technology of fermentation production and winemaking» studying the disciplines «Technology of malting», «Technology of brewing production», «Techno-chemical control of fermentation production and winemaking» are held in the workshop, as the conditions of technopark are as close as possible to the production conditions. Since the opening of the workshop, more than 60 students have acquired practical skills in the production of foam drinks.

On the basis of this equipment, young scientists of University conducted a number of significant scientific and experimental works:

— candidate of biological sciences, associate professor Baigaziyeva G.I., PhD Bayazitova M.M., master’s student Madet G. «Research of malting properties of triticale grain and development of technology for a new beer»;

— PhD Kekibayeva A.K., master Rasulova M., master’s student Abdushukurov Zh. «Development of special purpose beer technology with low gluten content» and etc.

Scientific and research work of students, master's students and doctoral students

At the training center, bakery technologists of the highest category Sergey Anatoliyevich Zemtsov, Pavel Besedin and others conduct training seminars, master classes for workers in the bakery and confectionery industry of Kazakhstan, as well as for students, master’s students, doctoral students and teachers of our university.

The training center was opened in February 2019 at «ATU» JSC.

The opening ceremony of training center was attended by: «Adil» LLP, representative of Bakaldrin company (Austria), general director Ushakova E.A., director of bakery and confectionery shops of «Becker & K» LLP Kaliyeva N.M., head of confectionery production company «Patissier» Lavrentiyeva Yu.G., regional representative of «Nizhny Novgorod Bread» NHL group of companies for Kazakhstan and Central Asia Baitymanova A., heads of the largest food industry enterprises, «Almaty yeast plant» JSC, «Bekker & K» LLP, «Adil» LLP, as well as students, master’s students, doctoral students and teachers of «Technology of bread products and processing industries» department of «ATU» JSC.

The main task of center is to involve student youth in practical experience, to awaken interest in new scientific knowledge that goes beyond the main educational programs.

At the training center, bakery technologists of the highest category Sergey Anatoliyevich Zemtsov, Pavel Besedin and others conduct training seminars, master classes for workers in the bakery and confectionery industry of Kazakhstan, as well as for students, master’s students, doctoral students and teachers of our university.

The functioning of such centers is important for the commercialization of the results of scientific and innovative activities of teachers, young scientists and students.