Amantaeva Almagul Kurmangalievna

Director of the Research Institute of Textile and Light Industry, Candidate of Chemical Sciences

Phone: 293 52 95 (ext. 139)

E-mail: a.amantaeva@atu.edu.kz

The Scientific Research Institute of Textile and Light Industry (SRITLI)

The Scientific Research Institute of Textile and Light Industry (SRITLI) is a scientific structural unit of JSC "Almaty Technological University," established in 2004. The purpose of SRITLI is the systematic planning and effective organization of scientific research, as well as participation in the training of highly qualified specialists.

SRITLI conducts both fundamental and applied scientific research across a wide range of areas in the textile and light industry, including:

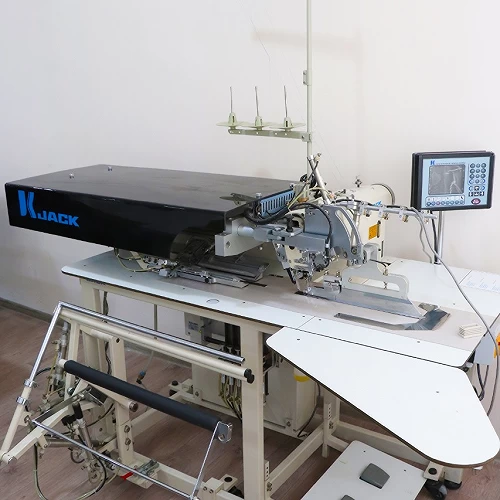

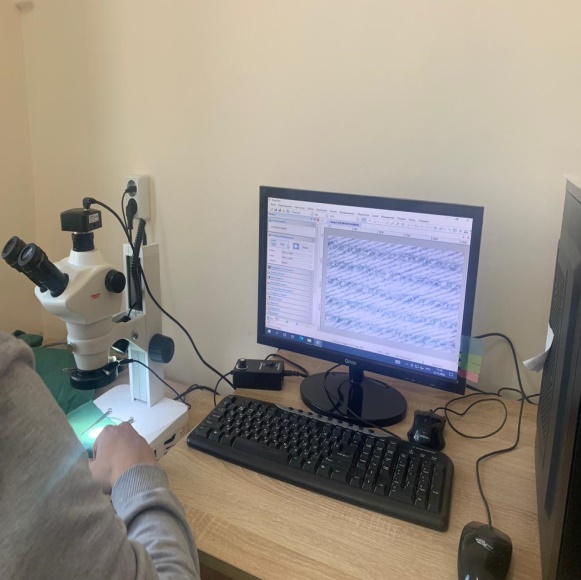

Between 2004 and 2024, SRITLI has developed a robust technical infrastructure equipped with a range of modern machinery, computer systems with specialized software, and automated systems for the design of garments.

Ongoing work includes the development and design of instruments and installations for:

The organizational structure of SRITLI includes:

Scientific Research Laboratory of Technology and Safety of Textile Materials(SRLTSTM)

Scientific Research Laboratory of Technology and Safety of Textile Materials(SRLTSTM) conducts scientific research in the processing of bast fiber crops, the improvement of wool carding technology for coarse-haired goats, and the application of nano- and biotechnology in the finishing of textile materials using various textile auxiliary agents.

SRLTSTM’s key research areas include:

Key Achievements of the SRLTSTM based on the results of scientific research conducted at the Scientific Research Laboratory of Technology and Safety of Textile Materials, and under the guidance of scientists from JSC "ATU," the following research projects have been successfully carried out:

Scientific Research Laboratory for the Design of Light Industry Products (SRLDLIP)

The Scientific Research Laboratory for the Design of Light Industry Products (SRLDLIP) conducts scientific research in the design of school uniforms, taking into account sociological, economic, functional, and hygienic factors; the creation of collections of seasonal and winter workwear for metallurgists; and the development of clothing sets made from innovative materials for burn victims and cancer patients.

SRLDLIP’s priority research areas include:

Key Achievements of SRLDLIP: As a result of scientific research conducted at the Scientific Research Laboratory for the Design of Light Industry Products under the guidance of scientists from JSC "ATU," the following research projects have been completed:

.png)

.png)

.png)

In 2004-2022, the technical base and methodological foundations for conducting scientific research and testing of materials were created at the Scientific Research Institute of Textile and Light Industry. The organizational structure of the Scientific Research Institute of Textile and Light Industry includes Scientific Research Laboratory of Technology and Safety of Textile Materials and the Research Laboratory for the Design of Light Industry Products.

The main achievements of the Scientific Research Laboratory of Technology and Safety of Textile Materials: Based upon the results of scientific research, on the base of the research laboratories of technology and safety of textile materials under the guidance of ATU scientists, the funded topics were carried out:

THE SCIENTIFIC RESEARCH LABORATORY FOR THE DESIGN OF LIGHT INDUSTRY PRODUCTS is technically equipped with a fleet of modern sewing equipment, computer equipment with appropriate software, automated systems for designing sewing products.

Priority directions of the Scientific Research Laboratory for the Design of Light Industry Products:

Also in Scientific Research Laboratory for the Design of Light Industry Products, work is underway on the development and design of devices and installations that allow measuring the noise level passing through a package of materials intended for special clothing; installations that allow determining the heat-protective properties of materials and clothing packages; installations for studying the deformation of materials under cyclic exposure, installations that allow investigating the wear resistance of clothing material packages.