1) Development of design documentation for a collection special clothes

2) Development of design documentation for school uniforms of the Republic of Kazakhstan

3) Do not use the trans-isomeromeric fluoride in the food, beverages or confectionery industry

4) Development of beer technology using non-traditional plant raw materials

Project topic: IRN No. AP08955357 “Development of highly efficient technology for producing bakery and flour confectionery products from composite flour mixtures without the use of sugar”

Relevance of the project

Recently, much attention has been paid to waste-free food production technologies. When processing sugar beets, only 15-30% of raw materials are used, the rest remains as waste. A certain part of this waste is used as secondary raw materials for the production of compound feed. But at the same time, they are unstable during storage, quickly sour, ferment, losing valuable components and polluting the environment.

In this regard, the use of dry sugar beet powders is relevant. Also, assortments of bakery and flour-confectionery products will be enriched with composite flour from leguminous crops, such as chickpeas, beans and others, which have beneficial vitamin properties.

Objective of the project

Development of innovative highly efficient technology for bakery and flour-confectionery products using flour of composite mixtures of leguminous crops and dried sugar beets in order to improve quality, beneficial properties, reduce the production process, increase labor productivity and improve the socio-economic indicators of bakery and flour-confectionery enterprises.

Expected results

As a result of the project, a technology for obtaining assortments of bakery and flour-confectionery products without the use of sugar will be developed, 2 master's degrees will be prepared, and at least 1 (one) article or review will be published in a peer-reviewed scientific publication in the scientific direction of the project, included in 1 (first), 2 (second) or 3 (third) quartiles in the Web of Science database and (or) having a CiteScore percentile in the Scopus database of at least 50 (fifty), or in print in the specified publications and at least 1 (one ) articles in a peer-reviewed foreign and (or) domestic publication with a non-zero impact factor (recommended by the Committee for Quality Assurance in Science and Higher Education).

Results achieved:

Technological modes for drying sugar beets have been developed and finely ground powder has been obtained from it. Recipes and technological regimes for the production of bakery and flour and confectionery products using powder from sugar beets and leguminous crops have also been developed. Assortments of bakery and flour-confectionery products were obtained using sugar beet powder and composite flour of leguminous crops. In order to exclude sugar from the recipe, sugar beet powder was used in the production of buns. Dried sugar powder contains about 70% sugar and 7.1% moisture. Compared to the recipe for a sugar bun, in the recipe for bakery and flour and confectionery products with sugar beet powder, differences in the amount of premium and first grade flour are established. It was also determined that flour from pulses, especially chickpea flour, strongly absorbs moisture. For this sample, first grade flour was added depending on the consistency of the dough

A comprehensive assessment of the quality of raw materials and developed bakery and flour and confectionery products (physical and chemical indicators, rheological properties, nutritional value, safety indicators) was carried out. The study of physicochemical, biochemical and microbiological parameters was carried out in the laboratory of the Research Institute of Food Safety. The following indicators were determined: the content of protein, fat, moisture, ash, fiber, carbohydrates, mineral elements (potassium, calcium, phosphorus, iron), vitamins (A, E, B1, B2, PP), heavy metals (Pb, Cd) , pesticides, mycotoxins, microbiological indicators (QMAFAnM, coliforms, mold, yeast) and others.

Members of the project research team:

1 Scientific supervisor: Muldabekova Bayan Zhaksylykovna (bayan_10.04@mail.ru)

https://is.ncste.kz/profile/23259 , Author ID in Scopus 56031648500

ORCID ID 0000-0003-1848-4288

2 Responsible executor: Yakiyaeva Madina Asatullaevna

yamadina88@mail.ru, https://is.ncste.kz/profile/15779,

Author ID in Scopus 57191979219

Researcher ID Web of Science AAL-7432-2020

ORCID ID 0000-0002-8564-2912

Researcher ID in Publons AAL-7432-2020

3 Tungyshbaeva Ulbala Oblbekovna, ulbala_84@mail.ru, https://orcid.org/0000-0003-0593-1130, Author ID in Scopus 57211350912

4 Suimbaeva Saltanat Malikovna, saltanat_suimbayeva@mail.ru, Author ID in Scopus 57927949900

5 Abdibek Alina Adilkhankyzy, alina.abdibek@mail.ru

List of publications on the project:

Project name: IRN AR09258901 Research and development of combined refrigeration systems with radiation cooling for industrial refrigeration and air conditioning

Source of funding: Science Committee of the Ministry of Education and Science of the Republic of Kazakhstan

Grant number: AP09258901/GF

Project implementation period: 2021–2023

Relevance:

Refrigeration machines make a significant contribution to the energy consumption of modern cities. Given that the number of refrigeration equipment in use is steadily increasing, there is a need to find ways to improve their energy efficiency.

Radiative cooling (English: Radiative Cooling) is a method of removing heat into the environment in the form of infrared radiation through the planet’s atmosphere into outer space. This cooling method is distinguished by the fact that it allows you to obtain a temperature below the ambient air temperature with minimal energy consumption.

The climate of Kazakhstan is favorable for the use of radiative cooling. However, the possibility of using radiative cooling depends on weather conditions. In this regard, to stably maintain the required temperature, radiation cooling should be used in conjunction with traditional refrigeration machines.

In continental climates, at certain times traditional refrigeration machines may not operate as efficiently as possible. Here in the summer they are forced to work at high ambient temperatures. If the heat of condensation of the refrigerant is removed to atmospheric air at +40°C, the condensation temperature rises above +55°C. This leads to a decrease in the coefficient of performance and causes increased energy consumption. The use of evaporative cooling condensers and various liquid cooling condensers to reduce the condensation temperature is not always possible due to the lack of fresh water. By using radiation cooling, it is possible to create a scheme for removing condensation heat, which allows you to simultaneously reduce the condensation temperature and eliminate the consumption of fresh water.

In winter, the use of traditional refrigeration machines is also necessary, despite the possibility of using natural cooling. During the cold season, radiative cooling can be used to directly remove heat from the object being cooled. In this way, cooling can be carried out without turning on the compressor of the refrigeration machine, which during certain periods of the year can lead to significant energy savings.

Project goal: to study the possibility of using radiation cooling in conjunction with a vapor compression refrigeration machine for industrial year-round refrigeration and air conditioning of fruit and vegetable storage facilities located in regions with a continental climate.

Expected and achieved results

As a result of the project, it is planned to develop and manufacture an experimental refrigeration chamber for storing apples, the cooling of which will be carried out through the combined action of a refrigeration machine and a radiation cooling system.

Results obtained for 2021:

Research group

Tsoi Alexander Petrovich - project manager, candidate of technical sciences (ORCID: http://orcid.org/0000-0002-3073-6698, Scopus: https://www.scopus.com/authid/detail.uri?authorId=57195570143 )

Granovsky Alexander Sergeevich - senior researcher (ORCID: http://orcid.org/0000-0002-1191-038X, Scopus: https://www.scopus.com/authid/detail.uri?authorId=57195570324)

Koretsky Dmitry Anatolyevich - junior researcher (ORCID: http://orcid.org/0000-0003-3110-8383)

Vorobyova Olga Dmitrievna - junior researcher (ORCID: https://orcid.org/0000-0001-7942-6562)

Tsoi Diana Aleksandrovna - senior researcher, candidate of technical sciences (ORCID: https://orcid.org/0000-0003-4059-7924, Scopus: https://www.scopus.com/authid/detail.uri?authorId= 57195566340)

Dzhamasheva Rita Adilovna - junior researcher (ORCID: https://orcid.org/0000-0002-4940-8336, Scopus: https://www.scopus.com/authid/detail.uri?authorId=57208567714)

Publications

Methodology for determining the main characteristics of a refrigeration system with removal of condensation heat due to radiation cooling / Tsoi A.P., Granovsky A.S., Dzhamasheva R.A. // Bulletin of Almaty Technological University. – 2021. – No. 3. – pp. 34-41. – https://doi.org/10.48184/2304-568X-2021-3-34-41

Patents

Pat. No. 35182 Republic of Kazakhstan, IPC F25B 25/00, F25B 23/00. Refrigeration system combined with a radiation cooling unit and a vapor compression machine / A. P. Tsoi, A. S. Granovsky, D. A. Tsoi. – statement 05/22/2020, publ. 07/09/2021, Bulletin. No. 27

Project topic: IRN AR09058293 Development of technology for the production of dietary immunostimulating confectionery products based on the processing of local plant raw materials

Relevance of the project

The popularity of confectionery products according to the statistics of Kazakhstan is growing, on this basis this segment of products can be a carrier of functional ingredients that determine their directed action in the prevention of viral and other mass nutritional diseases.

Attention should be paid to the selection of ingredients based on plant extracts, vitamins, probiotics that strengthen immunity by improving biochemical processes in the body.

In this regard, the production of immunostimulating confectionery products enriched with biologically active substances of plant origin seems to be an urgent task for the food industry.

The problem - insufficient number of implemented in production research on the development of technology of specialised confectionery products for the population of Kazakhstan.

Solution - sparing technology of production of dietary immunostimulating confectionery products on the basis of local plant raw materials.

Project objective

The aim of the work is to develop resource-saving complex technology of production of dietary immunostimulating confectionery products (candies, marmalades, lollipops, etc.), made from natural, inexpensive, local plant raw materials without added sugar, enriched with vital nutrients.

Translated with DeepL.com (free version)

Achieved results:

10 scientific papers have been published, including:

- 2 articles in the journal in the Scopus database in the journal Eastern-European journal of Enterprise technologies (percentile 42);

- 2 article in the journal KKSON;

- 6 theses in international conferences.

Within the framework of the project, 5 recipes and technology of pastilomarmelade products were developed, given in the technological instruction No. TI-AO-990840000359-01-2022 dated 08.07.2022, an application was filed for the Patent of the Republic of Kazakhstan for invention No. 2022/0427.1 dated 08.07.2022 "Compositions for pastilomarmelade products of functional purpose (variants) and method of preparation", also, 3 recipes and technology for the production of caramel lollipops on sugar and maltitol have been developed, given in the technological instruction No. TI-AO-990840000359-02-2022 from 02.09.2022, 3 formulations and technology for the production of functional marshmallows have been developed, given in the technological instruction No. TI-AO-990840000359-03-2022 , approved on 17.10.2022.

. Safety indicators, rheological, physico-chemical and orgonoleptic properties of ready confectionery products were determined, release of biologically active compounds from samples of of bunched pastilla and marshmallow at digestion in vitro is investigated. The content of probiotics in ready pastilomarmalade products was studied. Recipes were developed and sparing technological modes of preparation were selected.

Main constructive and technical-economic indicators: Economic efficiency indicator will reach maximum results at realisation and full staffing of production according to the project after completion of the payback period and overcoming the break-even point. Profitability of production 29,8,%, payback period 1,1 year. At minimum costs for equipment and start-up of the process the economic effect will be 88%.

Degree of implementation: The technology of pastilomarmaladnyh products introduced in the production conditions of IP "VM".

Efficiency: Implementation of the research results contributes to the improvement of the quality of human life through regular consumption of developed products, which can increase human immunity.

Field of application: Confectionery industry. Consumers: Children from 3 years of age, people leading a healthy lifestyle, with low immunity, with problems with diabetes and obesity.

Members of the research group of the project:

Pronina Yuliya Gennad’yevna (Scopus Author ID 57191589734, ResearcherID Web of Science number: AAW-4474-2020, ORCID https://orcid.org/0000-0003-0395-3379

Nabieva Zhanar Serikbolovna (Scopus Author ID 56031451100 and 57203549350, ResearcherID Web of Science Number: ABE-5638-2021, ORCID https://orcid.org/0000-0001-7258-746X

Bazylkhanova(Tasturganova) Elmira Chaimaksutovna (Scopus Author ID 5720375910, ResearcherID Web of Science Number: ABE-9543-2021, ORCID https://orcid.org/0000-0002-7854-1523

Shukesheva Saule Yerbolatovna (Scopus Author ID 57203547092, ResearcherID Web of Science Number: ABE-5500-2021, ORCID https://orcid.org/0000-0002-7275-8385 )

Belozertseva Olga Dmitrievna (Scopus Author ID 57350330600, ORCID http://orcid.org/0000-0002-2149-9811 )

Samadun Abdysemat Isamidinuly (ORCID http://orcid.org/0000-0002-5286-5175 )

Kazhymurat Asemai Talgatkyzy (Scopus Author ID 57203803583, Researcher ID Web of Science Number: M-9468-2015, ORCID https://orcid.org/0000-0001-5359-5528 )

Urazbekova Gulzhan Yerbolatovna (Scopus Author ID 58642395500, Researcher ID Web of Science Number: JTR-6900-2023, ORCID https://orcid.org/0000-0003-3909-0130 )

List of publications on the project:

Pronina, Y.; Kulazhanov, T.; Nabiyeva, Z.; Belozertseva, O.; Burlyayeva, A.; Cepeda, A.; Askarbekov, E.; Urazbekova, G.; Bazylkhanova, E. Development of a Technology for Protein-Based, Glueless Belevskaya Pastille with Study of the Impact of Probiotic Sourdough Dosage and Technological Parameters on Its Rheological Properties. Foods 2023, 12, 3700. https://doi.org/10.3390/foods12193700 (Food Science - Quartile Q1 Percentile -78th)

Burlyaeva A.S., Pronina Yu.G., Belozertseva O.D., Nabieva Zh.S., Samadun A.I. Investigation of the effect of herbal additives on the immunostimulating properties of a pastille product. Bulletin of the Almaty Technological University. 2023;1(3):100-108. https://doi.org/10.48184/2304-568X-2023-3-100-108

Zhakhanova A.,Shugyla T., Nabiyeva Zh. S., Zhexenbay N., Pronina Yu. G. Functional bioproducts – protein enriched pastilla //Staliy lantsyug kharchuvannya ta bezpeka kryz nauku, znannya ta biznes [Electronic resource]: tezi dopovidey Mizhnarodnoi naukovo-praktichnoi konferentsii, 18 travnya 2023 R. / Derzhavny biotechnological University. – Harkiv. – 2023. pp. 101-102. http://dspace.puet.edu.ua/bitstream/123456789/12883/1/%D0%97%D0%B1%D1%96%D1%80%D0%BD%D0%B8%D0%BA%20%D1%82%D0%B5%D0%B7_.pdf

Kazhymurat A., Pronina Yu., Bazylkhanova E., Nabiyeva Zh., Samadun A. Study of quality indicators of caramel lollips with immunostimulating properties // Proceedings of the XXV International Scientific and Practical Conference «Theoretical foundations of scientists and modern opinions regarding the implementation of modern trends». San Francisco, USA, 2023. pp. 397-400. https://isg-konf.com/theoretical-foundations-of-scientists-and-modern-opinions-regarding-the-implementation-of-modern-trends/

Bazylkhanova E., Pronina Yu., Improving the technology of production of immunostimulating confectionery // Proceedings of the XXV International Scientific and Practical Conference «Theoretical foundations of scientists and modern opinions regarding the implementation of modern trends». San Francisco, USA, 2023. pp. 414-415. https://isg-konf.com/theoretical-foundations-of-scientists-and-modern-opinions-regarding-the-implementation-of-modern-trends/

Bazylkhanova E., Pronina Yu., Nabiyeva Zh., Kazhymurat A., Samadun A. Research of antioxidants in functional marshmallows// The 21th International scientific and practical conference «Scientist and methods of using modern technologies» (May 30-june 02,2023) Melbourne, Australia. International Science Group. – P. 400-402 https://isg-konf.com/scientists-and-methods-of-using-modern-technologies/

Improving the technology of fruit and berry confectionery products for functional purposes: monograph / Yu.G. Pronina, O.D. Belozertseva, Zh.S. Nabieva, E.Ch. Bazylkhanova, - Almaty: DELUXE PRINTERY LLP, 2023. – 401 p. https://library.atu.edu.kz/files/281967/

Patent for the invention of the Republic of Kazakhstan No. 36422 "Fruit and berry marmalade (variants) and the method of its preparation", publ. 10/20/2023 Issue No. 42. Authors: Pronina Yu.G., Belozertseva O.D., Shukesheva S.E., Nabieva J.S., Samadun A.I. https://gosreestr.kazpatent.kz/Invention/Details?docNumber=360002

Patent for a utility model of the Republic of Kazakhstan No.8537 "Composition of caramel candies (variants)", publ. 10/20/2023 Issue No. 42. Authors: Pronina Yu.G., Kazhymurat A.T., Belozertseva O.D., Bazylkhanova E.Ch., Nabieva Zh.S. https://gosreestr.kazpatent.kz/Utilitymodel/Details?docNumber=378713

ProninaYu.G, NabiyevaZh.,Belozertseva O., Shukesheva S., SamodunA.Identification of the influence of technological factors on the growth and development of lactic acid microorganisms in pastille marmalade products enriched with lactic acid starters// Eastern-European Journal of Enterprise Technologies. 4/11(118). – 2022. – P.68-78. http://journals.uran.ua/eejet/article/view/263111/26002 (article – Scopus, CiteScore percentile in the FoodScience section — 42 )

Pronina Yu.G., Nabieva Zh.S., Belozertseva O.D., Samadun A.I. Studying the effect of functional ingredients on the vitamin composition of immunostimulating pastilomarmelade products // Bulletin of the Almaty Technological University, Almaty, — 2022. -№3(137). – Pp.177-185. https://www.vestnik-atu.kz/jour/article/view/1090 Committee for Quality Assurance in the Field of Science and Higher Education of the Ministry of Science and Higher Education of the Republic of Kazakhstan

Pronina Yu.G., Bazylkhanova E.Ch., Nabieva Zh.S., Belozertseva O.D., Kazhymurat A.T., SamadunA.I.Analysis of organoleptic parameters of lollipops based on sea buckthorn and St. John's wort//collection of articles XLVIIimedunar. nauchn.-practical conference "EurasiaScience"/ Moscow: "Scientific Publishing Center "Relevance.RF", 2022. pp. 76-77 (thesis) http://xn--80aa3afkgvdfe5he.xn--p1ai/ES-47_originalmaket_N.pdf

Nabieva Zh.S., Pronina Yu.G., Urazbekova G.E., Zhakhanova A.N., Burlyaeva A.S. The use of probiotics in the technology of immunostimulating confectionery// Collection of Mat. international scientific Journal.-practical conference "Innovative development of food, light industry and hospitality industry" dedicated to the 65th anniversary of Almaty Technological University." Almaty, 2022. pp.153-154 (thesis) https://drive.google.com/file/d/1k4AtpkrxNbiL1w7yu8wME9Syg3LFvicv/view

Burlyaeva A.S., Pronina Yu.G., Belozertseva O.D. Improving the technology of production of whipped confectionery products for functional purposes//Collection of mat. international scientific.-practical conference "Innovative development of food, light industry and hospitality industry" dedicated to the 65th anniversary of Almaty Technological University." Almaty, 2022. pp.181-182 (thesis) https://drive.google.com/file/d/1k4AtpkrxNbiL1w7yu8wME9Syg3LFvicv/view

Belozertseva O., Baibolova L., Pronina Yu.G., Cepeda A., Tlevlessova D. The study and scientifical substantiation of critical control points in the life cycle of immunostimulating products such as pastila and marmalade //Eastern-European Journal of Enterprise Technologies. 5/11(113). – 2021. – P.20-28 https://doi.org/10.15587/1729-4061.2021.241526

Pronina Yu.G., Bazylkhanova E.Ch., Nabieva Zh.S., Belozertseva O.D., Kazhymurat A.T., Samadun A.I. The current state of research and production of dietary immunostimulating confectionery products based on vegetable raw materials//Sb. mater. IX International scientific practice. conf. "SCIENCE AND EDUCATION IN THE MODERN WORLD: CHALLENGES OF THE XXI CENTURY". Technical sciences. – Nur Sultan, 2021. pp. 54-58. http://www.bobek-kz.com/

Pronina Yu.G., Nabieva Zh.S., Shukesheva S.E. Prospects for the use of lactic acid microorganisms in the production of marmalade//Collection of articles in Integration of Education, Science and Business in Modern Environment: Summer Debates: abstracts of the 3rd International Scientific and Practical Internet Conference, August 11-12, 2021. – Dnipro, Ukraine, 2021. pp. 413-415. http://www.wayscience.com/wp-content/uploads/2021/08/Materials-of-conference-11-12.08.2021-1.pdf

Pronina Yu.G., Nabieva Zh.S., Bazylkhanova E.Ch., Belozertseva O.D., Samadun A.I. Investigation of the vitamin composition of medicinal herbs in the development of immunostimulating confectionery products. Bulletin of the Almaty Technological University, Almaty, — 2021. -№3(133). – Pp.25-33. https://doi.org/10.48184/2304-568X-2021-3-25-33

Pronina Yu.G., Nabieva Zh.S., Shukesheva S.E. Substantiation of the use of immunostimulating medicinal plants in the technology of confectionery pastille and jelly products//Mater. international scientific practice. Conference "Innovative development of food, light industry and hospitality industry" dedicated to the 30th anniversary of independence of the Republic of Kazakhstan. – Almaty: ATU, 2021. pp. 147-148. https://drive.google.com/file/d/1AOABZDphOPb8TxMwcmTDfxWO8VldJQ_W/preview

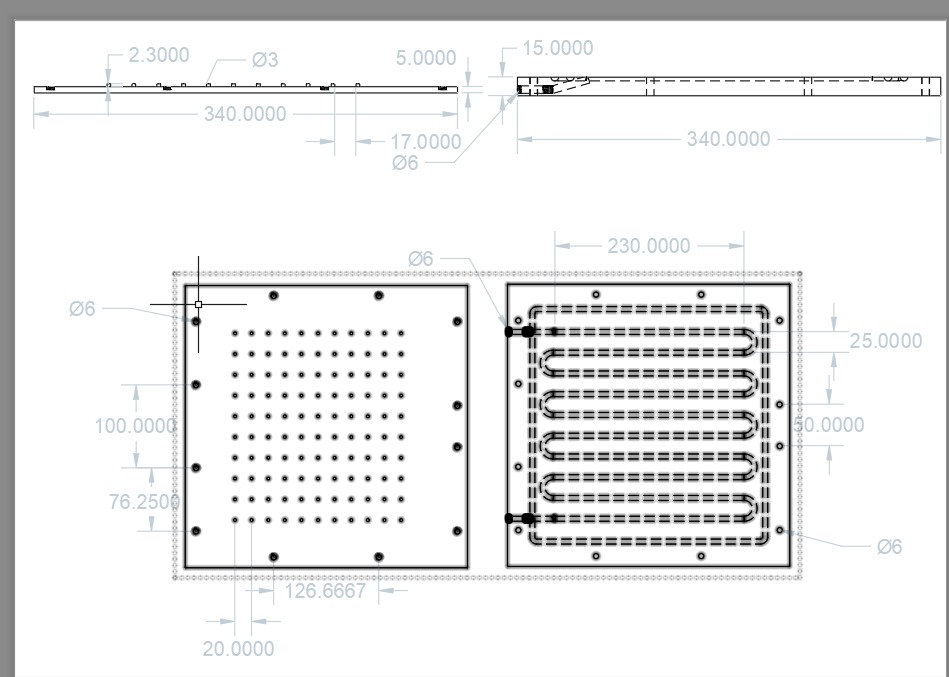

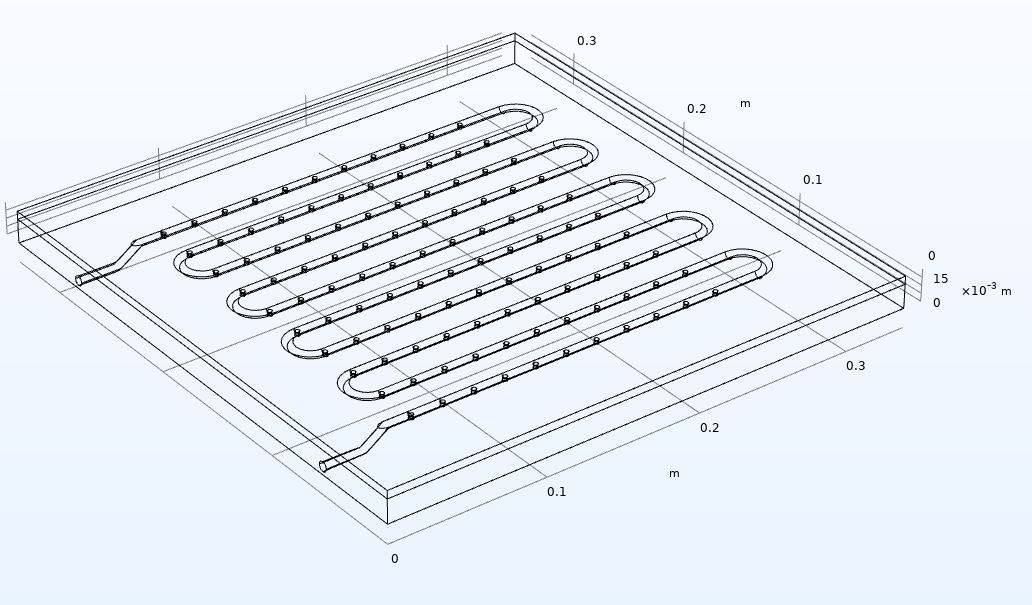

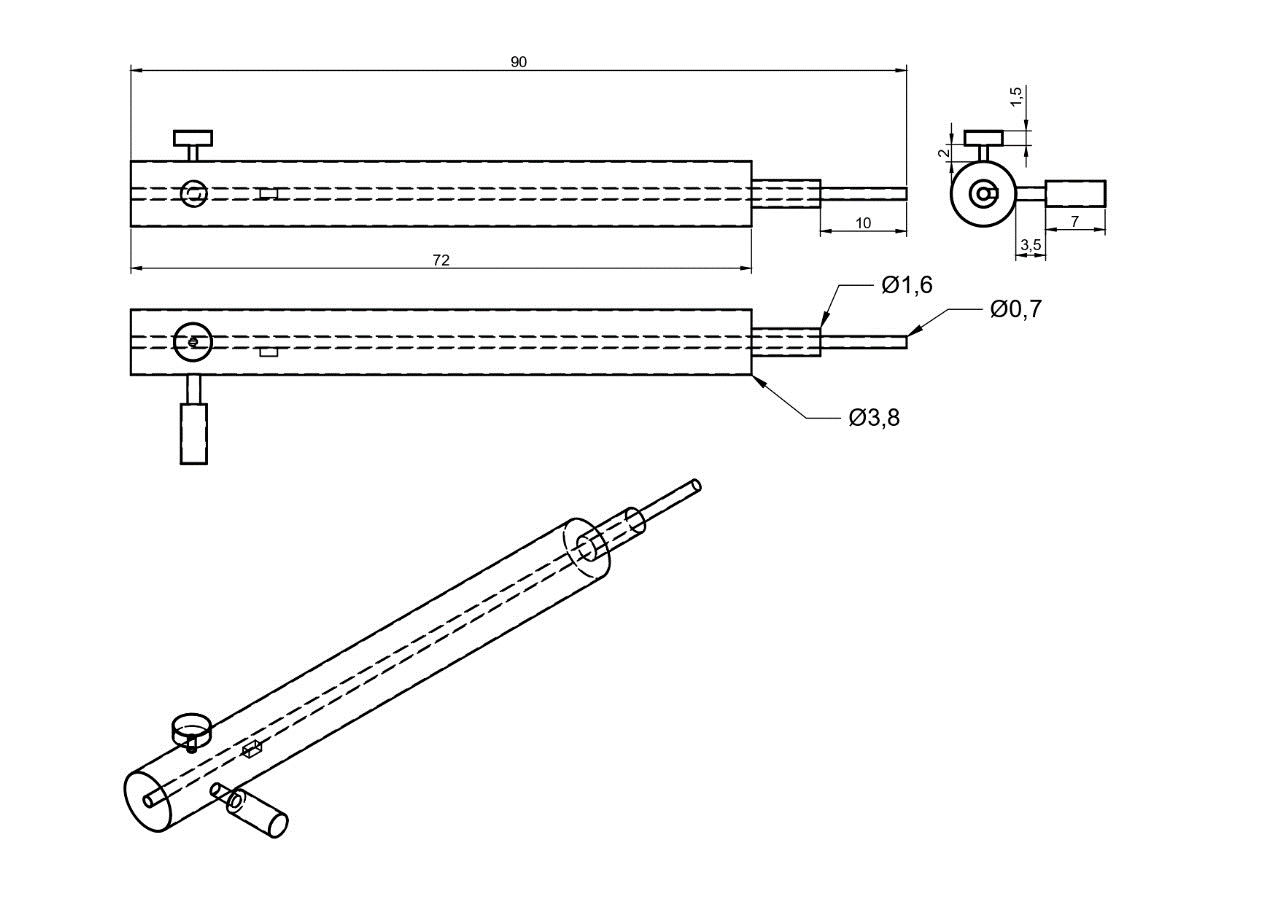

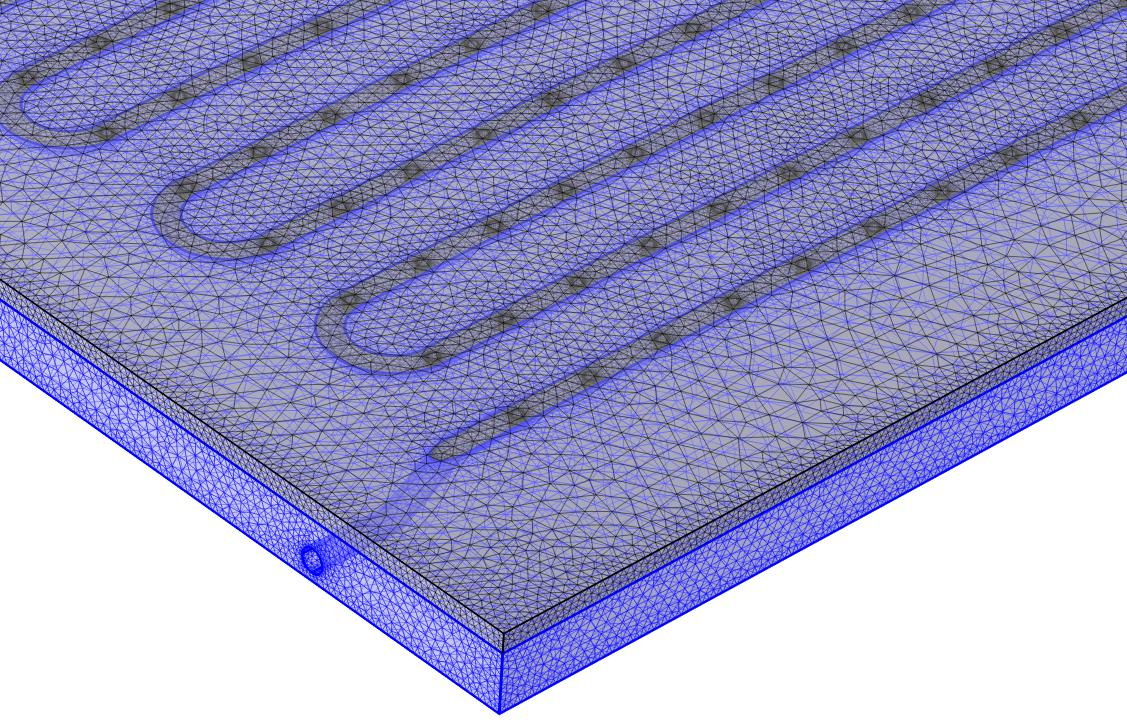

Project topic: AP19576644 Development of a universal cooled cryosurface for research of physicochemical, optical properties of substances from room up to 80 K.

The relevance of the project:

In the message to the people of Kazakhstan "Kazakhstan's way-2050: a single goal, a single interest, a single future" the President of the country noted: Development of new knowledge and technologies is the main way to increase the potential of the country. Cryogenics is the division of physics into low temperatures, which studies the regularity of changes in the properties of different substances in the conditions of extremely low ("cryogenic") temperatures. In addition, this term refers to the technology and hardware-methods of work at low temperatures. It is also defined as the field of science, covering research, development and application of cryogenic technology. Heat-exchanging devices relate to the basic elements of cryogenic systems, which ensure the regeneration of heat, without which it is impossible to obtain low temperatures. In heat exchangers, physical processes of exchange of thermal energy between streams of substances with different temperatures occur. These processes are subject to the general laws of thermodynamics, but at low temperatures a whole range of complementary factors arises, without taking into account the need to design efficient and compact devices. Part of the development of this project, and it is the cryopower that represents one of the species of heat exchangers, as a recuperator. The classic type of such heat exchanger is a tubular heat exchanger. To increase the heat transfer when necessary inside the pipes we will use plate-ribbed surfaces. An important task is the development of a necessary cryogenic pump for liquid nitrogen. The performers of the project are constantly conducting research in this direction. Already created the installation on the definition of heat conduction at low temperatures with the use of a cryopump on the basis of a gas lift it was pushed to the development of a cryopump for cryopanels.

Purpose of the project:

Development of a panel for cooling, working with materials, scientific research of optical, physico-chemical properties of materials in the low-temperature range. To achieve this goal, the most difficult and urgent associated tasks are the creation of a measuring cell and a pump with an adjustable flow rate of liquid nitrogen.

Objectives of the project: The achievement of the project goal is ensured by the following tasks:

Expected results

1) Implementation of publications in 2023-2025: - 2 (two) articles in peer-reviewed scientific publications in the scientific direction of the project, indexed in the Science Citation Index Expanded of the Web of Science database and (or) having a CiteScore percentile in the Scopus database of at least 50 (fifty); - either 1 (one) article in a peer-reviewed scientific publication on the scientific direction of the project, indexed in the Science Citation Index Expanded of the Web of Science database and (or) having a CiteScore percentile in the Scopus database of at least 50 (fifty) and the act of implementation; - either 1 (one) article or review in a peer-reviewed scientific publication included in the 1st (first) quartile of the impact factor in the Web of Science database; - 2 (two) articles or reviews in a peer-reviewed foreign or domestic publication recommended by COXON;

2) Publication of monographs, books and (or) chapters in the books of foreign and (or) Kazakh publishers - No;

3) Obtaining patents in the Kazakhstan Patent Office - Yes;

4) Development of scientific and technical, design documentation - Yes;

5) Dissemination of results. Participation with reports at international conferences. Publication in journals with an impact factor. Consumers of results: - Universities of physical and technical profile in the form of new special courses; - Scientific medical, biological, petrochemical organizations for working with samples at low temperatures (80-300 K). - Ice cream manufacturers in the form of purchase of developed equipment; - Cell phone repair organizations; - Scientific institutes for the study of samples at low temperatures.

6) The result of the project is the creation of a universal cryosurface, including for scientific research of samples at cryogenic temperatures. The results will also be the receipt of new applied data on the properties of materials at low temperatures. The results of the study will be published in articles in rating journals, and will also be reported at major scientific conferences. A master's thesis and at least two bachelor's theses will be prepared. At least 4 jobs will be created for highly qualified young professionals; With increased demand, it will be possible to commercialize the scientific results obtained; Application of scientific results: • The possibility of further use of the created installations for scientific research of various materials and educational processes on the basis of ATU. • Formation of physical and technological bases for the production of cryogenic equipment; • Training of specialists in the field of cryogenic technologies and materials science; The results will have a certain impact on the development of low temperature physics and cryogenic technologies of the Republics of Kazakhstan.

Members of the project's research team:

Achieved results:

Project topic: IRN AR19680380 Development of technology for obtaining ingredients of animal - collagen peptide hydrolysates and creation of functional meat products

Relevance of the project

Scientific novelty consists in the development of collagen hydrolysate from secondary meat raw materials based on the use of enzymatic hydrolysis.

At present, much attention is paid to the preservation of human health in conditions of increasing influence of negative influences, such as environmentally unfavorable living conditions; heavy and harmful working conditions; frequent stressful situations. Therefore, active research is conducted to search for new functional ingredients and study the mechanisms of their action at the molecular, cellular and organismal levels. Interest in functional foods is due to the fact that food products are no longer just a means of satisfying hunger and providing the necessary nutrients to a person, consumers are looking for products that contribute to both health promotion and correction of certain pathologies. The growing demand for functional foods is also linked to the global rise in health care prices, gradually increasing life expectancy and people's desire to lead active lifestyles. The project aims to address the fundamental problem of providing the population with functional products with proven biological properties and improved organoleptic characteristics.

As the main components that give the product functional orientation will be used protein hydrolysates of by-products obtained by enzymatic hydrolysis, plant raw material goji berries, possessing as it was shown proved in the course of the project № state registration "0115RK01497 Study of functional and biocorrective characteristics of plant-animal complexes and development on their basis technology of national meat products of new generation using local raw materials" biocorrective properties.

Project objective

The aim of the project is to develop a technology for obtaining ingredients of animal origin - collagen peptide hydrolysates and creating functional meat products based on them to solve the problem of providing the population with functional products with proven biological properties and improved organoleptic characteristics.

Expected results:

According to the results of the project implementation, at least 3 (three) will be published for the entire implementation period articles and (or) reviews in peer-reviewed scientific publications in the scientific direction of the project, indexed in the Science Citation Index Expanded of the Web of Science database and (or) having a CiteScore percentile in the Scopus database of at least 35 (thirty-five), at least 2 (two) articles or reviews in a peer-reviewed foreign or domestic publication recommended by the Committee for Quality Assurance in Science and Higher Education of the Ministry of Science and Higher Education of the Republic of Kazakhstan. An application for a patent for a utility model of the Republic of Kazakhstan will be filed. upon completion of the project, there will be: - The use of by-products for the production of peptide hydrolysates of collagen is justified. - Justification of the use of an enzyme preparation for the production of peptide hydrolysates of collagen. - Optimal conditions of enzymatic hydrolysis of by-products have been investigated. - The technology of peptide hydrolysates of collagen from by-products obtained by enzymatic hydrolysis has been developed. - The organoleptic and physico-chemical parameters of the developed collagen peptide hydrolysate were evaluated. - The formulation and technology of boiled sausage products (boiled sausage, sausages, sausages) with the use of peptide collagen hydrolysates has been developed. - An assessment of the organoleptic and physico-chemical parameters of the developed hydrolysate, as well as safety indicators of the developed meat products, was carried out. - The calculation of the economic efficiency of the developed hydrolysate, which is able to compete with foreign analogues in terms of its quality indicators, has been carried out. As a result of the conducted research, the technology of enzymatic processing of secondary raw materials of the meat processing industry into a valuable protein product with the prospect of application in the food industry will be developed. With the help of an enzyme preparation, hydrolysis will be carried out under controlled conditions, and the resulting protein hydrolysate in the form of animal protein will be used in the production technologies of boiled sausages. In general, the project promotes import substitution, as animal protein is imported to Kazakhstan. An additional advantage of the project is that the resulting protein product will meet the requirements of Halal, since pork pepsin will not be used in the proposed technology. The technology of obtaining a protein product can be used to develop basic educational material for the Department of "Food Technology" of the Faculty of Food Production of Almaty Technological University. The results obtained will contribute to the development of domestic biotechnological industries and the use of high-tech technologies in the food production and processing industry. The technology has the prospect of commercialization in the form of organizing a technological cycle at existing meat processing enterprises or in the form of organizing independent startups.

Members of the research group of the project:

Uzakov Yasin (Scopus Author ID 55968622400, ORCID: 0000-0002-6449-3102).

Kaldarbekova Madina (Scopus Author ID 57211610217 и Researcher ID Web of Science ID: ABE-4821-2021, https://publons.com/researcher/4813068/madina-kaldarbekova/, ORCID: 0000-0001-7258-746X).

Kozhakhiyeva Madina (Scopus Author ID 57200582885, ORCID: 0000-0001-5767-5154 Researcher ID Web of Science: https://publons.com/researcher/5135361/madina-kozhakhiyeva/).

Makangali Kadyrzhan (Scopus Author ID 57203767726. ORCID: 0000-0003-4128-6482. Researcher ID: AAR-1107-2020).

Mukhtarkhanova Rauan (Scopus Author ID 56862350200. ORCID: 0000-0001-8731-5600. Researcher ID Web of Science: https://www.webofscience.com/wos/author/record/43194374).

Kuzembayeva Gaukhar (Scopus Author ID 57221642732. ORCID: 0000-0003-0558-9531. Researcher ID Web of Science: https://publons.com/researcher/5135332/gaukhar-kuzembayeva/).

Vostrikova Natalia (Scopus Author ID 56034525000, Researcher ID Web of Science https://publons.com/researcher/2549517/natalia-vostrikova/. ORCID: 0000-0002-9395-705X.

Yessengaziyeva Aliya (Scopus Author ID 58366619200, ORCID: 0000-0003-2314-2995).

Abilmazhinova Nazym (Scopus Author ID 56862189400, https://www.scopus.com/authid/detail.uri?authorId=56862189400).

Tuleshev Zhanibek.

Tortay Arsen.

Project topic: IRN No. AR19677701 “Development of technologies for processing fat and moisture-containing waste from food production into feed products of the agro-industrial complex”

Relevance of the project

In the republic, in the production of agricultural feed products, the main problem is the use of a large amount of grain, which leads to an unbalanced composition, a decrease in quality and an increase in price. For example, in the recipes of domestic compound feeds, grain raw materials make up more than 70-75% (up to 80% or more), and in the USA and Europe this figure is 40-48% due to the use of food waste.

Another problem is the energy intensity of technologies or their absence at all for processing large-scale fat and moisture-containing food waste into non-grain raw materials, which improves the quality and reduces the cost of agricultural feed products. Therefore, the idea of the project is to solve these problems by creating extrusion technologies to achieve the level of foreign indicators.

Objective of the project

Development of innovative technologies for processing large-scale fat and moisture-containing waste from food production into raw materials, increasing the quality and reducing the cost of feed products of the agro-industrial complex, namely the processing of fat-and-oil, brewing, and sanitary waste harnoy and other productions into non-grain raw materials for partial or complete replacement of grain and other components of feed.

Expected results

The main results of research corresponding to the achievement of the project goal will be regulatory and technical documentation consisting of: technological instructions; technological regulations; technological process.

Technical specifications will be developed and approved at the stage of commercialization of research results.

The area of application and target consumers of each of the expected results are the feed industry, oil and fat and breweries, sugar factories, livestock and poultry farms and others.

Further in the research process, it is planned to obtain a patent from the Kazakhstan Patent Bureau.

The impact of the expected results on the development of the main scientific direction and related areas of science and technology is that they contribute to the further development of extrusive technologies in feed production, livestock farming, poultry farming and related areas - food industry.

The project is submitted to a competition with the aim of carrying out scientific research work with subsequent commercialization of the scientific results obtained, since in the republic the deficit of mixed feed reaches more than 50%, and the proposed technology will allow significantly reduce the cost and increase the efficiency of compound feeds.

The economic effect of the project results is as follows. Currently, the processing (drying) of large-scale fat and moisture-containing waste from the food industry is mainly carried out on drum dryers, which, for example, with a productivity of 1.5 tons / hour for raw materials, spend 23 1 kW/hour of electricity plus 450 – 511 liters per hour heating or diesel fuel in the amount of more than 116.0 thousand tenge.

In the same time, an endrgeth-euthered, with extruder of a millet, soy, barley, corn, peas an extruder PE-900 Ushk, produces from 1.3 to 1.8 tons/chas, compensates for a all 97 kW/chasu but a sum of 1.65 thousand thousand. tenge without the use of additional liquid fuel.

Thus, the costs for drum dryers are 72.5 thousand tenge per 1 ton, and for extruders – 1.1 thousand tons per 1 ton, i.e. the economic effect is more than 71.4 thousand tenge per 1 ton of product.

It should be taken into account that the technology for processing fat and moisture containing food waste is combined with extrusion technology for grain and legume components of mixed feed and therefore there is no additional technology for processing food waste , for example, in the form of drying lines.

It should be taken into account that the mixture for extrusion can consist of 50% grain legumes, feed components and up to 50% fat and moisture containing food waste. Therefore, assuming that to process 100% fat and moisture containing food waste, not 97 kW/hour of electricity will be required, but 2 times more - 194 kW/hour for the amount of 3.3 thousand tenge. Even in this case, the economic effect of the proposed technology will amount to 69.2 thousand tenge per 1 ton of the final product.

Will be published:

- at least 3 (three) articles and (or) reviews in peer-reviewed scientific publications, indexed in the Science Citation Index Expanded of the Web of Science database and (or) having a Cite Score percentile in the Scopus database of at least 35 (thirty-five);

- or at least 2 (two) articles and (or) reviews in peer-reviewed scientific publications, indexed in the Science Citation Index Expanded database of the Web of Science and (or) having a percentile of Cite Score in the Scopus database of at least 35 (thirty-five) and not less than one (1) patent included in the Derwent Innovations Index database (Web of Science, Clarivate Analytics);

- and also at least 1 (one) article or review in a peer-reviewed foreign or domestic publication recommended by the Committee for Quality Assurance in the Field of Science and Higher Education;

- or at least 2 (two) articles and (or) reviews in peer-reviewed scientific publications included in the 1st (first) and (or) 2nd (second) quartile by impact factor in the Web of Science database and (or) having a percentile by CiteScore in the Scopus database is not less than 65 (sixty-five).

Results achieved:

At food production enterprises - oil and fat, brewing, sugar enterprises, research was carried out, waste samples were taken, and the advantages and disadvantages of existing waste processing technologies were determined.

At the Koksu sugar plant, the brewery of JSC IP "Efes Kazakhstan" and the oil and fat plant of LLP "EFKO ALMATY", samples of wet waste were taken for processing filter sludge, and the advantages and disadvantages of existing waste processing technologies were also determined.

The chemical composition of fat- and moisture-containing waste from food production (soap stock, fatty bleaching clay, deodorization waste, phosphatides, brewer's grains, brewer's yeast, sugar beet pulp and others) has been studied. The chemical composition of fat- and moisture-containing waste from food production has been determined.

Waste from various brewing, oil and fat and sugar processing enterprises was studied in the accredited laboratory of Almaty Technological University. The content of dry matter, crude protein, crude fiber, sugar, starch, crude fat, minerals, carotene, vitamins E and B1, ash, neutral fat, unsaponifiable and waxy substances, SiO2, Al2O3, pectin substances, nitrogenous organic substances, in including nitrogen, pH, alkalinity, acidity and soap. And, accordingly, test reports were received.

An extrusion technology and laboratory installation have been developed for the joint processing of large-scale fat- and moisture-containing waste from food production (soap stocks, fatty bleaching clay, deodorization waste, phosphatides, brewer's grain, brewer's yeast, pulp). sugar beet and others) with plant components of production feed for animals and birds , reducing their cost and increasing efficiency.

An extrusion technology and laboratory installation have been developed for the joint processing of large-scale fat- and moisture-containing waste from food production and animal feed with plant components.

Members of the project research team:

1 Scientific supervisor: Iztaev Auelbek, Doctor of Technical Sciences, Professor, Academician of the National Academy of Sciences of the Republic of Kazakhstan, auelbekking@mail.ru, H-index - 7, Scopus Author ID 57204950041, ORCID ID 0000-0002-7385-482X

2 Responsible executor: Yazykbaev Erkin, Candidate of Technical Sciences yerkinkz@rambler.ru

3 Yakiyaeva Madina, PhD, associate professor, postdoctoral fellow, yamadina88@mail.ru, https://is.ncste.kz/profile/15779, H-index - 7, Author ID in Scopus 57191979219, Researcher ID Web of Science AAL-7432-2020, ORCID ID 0000-0002-8564-2912

4 Mukhtarkhanova Rauan, Candidate of Technical Sciences, rauan_78@mail.ru, https://orcid.org/ 0000-0001-8731-5600 , Author ID in Scopus 56862350200

5 Moldakarimov Almaz, master, 3rd year PhD student, mister_almaz89@mail.ru, https://orcid.org/0000-0001-8309-9285, Author ID in Scopus 57992129700

6 Mamyraev Maksat, master, 3rd year PhD student, maks1690@mail.ru

7 Samadun Abdysemat, master, 3rd year PhD student, abdu.93_93@mail.ru, https://orcid.org/0000-0002-5286-5175, Author ID in Scopus 57073938500

Project topic: IRN No. AR19174427 “Development of technology for long-term storage of walnuts”

Relevance of the project

Walnuts are among the products most at risk of oxidative spoilage during storage, transportation and sales. The lack of a traceability system for purchased batches of nuts at the stages of production, logistics and sales, as well as the lack of objective methods for assessing the potential level of shelf life, leads to incorrect determination of the shelf life of walnuts, and as a result, more than 30% of walnuts with signs of rancidity are sold in retail chains. Therefore, an important task in organizing the distribution and sale of nuts is, first of all, to develop a methodology for determining and extending the shelf life of a specific batch of walnuts, depending on the initial values of physical and chemical parameters, and determining the possibility and necessity of increasing the shelf life of nuts.

Objective of the project

Development of technology for long-term safe storage of walnuts grown in Kazakhstan using ozone, ion-ozone and radiation treatment and establishment of optimal processing and storage modes.

Expected results

- the dynamics of enzymatic and non-enzymatic hydrolytic and oxidative processes occurring in walnuts (Kazakh varieties) under different storage temperature conditions will be studied;

- physicochemical, microbiological indicators of walnuts (Kazakh varieties) will be determined before and after treatment with ozone, ion-ozone and radiation;

- dependences of the activity of oxidative and hydrolytic processes occurring during storage of walnuts (Kazakh varieties) in walnuts on storage temperature will be identified;

- plans for full-factorial experiments will be drawn up and optimal processing and storage regimes will be established;

- the shelf life of walnuts (Kazakh varieties) in shell and without shell will be determined.

- at least 2 (two) articles will be published in journals from the first three quartiles by impact factor in the Web of Science database or having a CiteScore percentile in the Scopus database of at least 50.

Results achieved:

The dynamics of enzymatic and non-enzymatic hydrolytic and oxidative processes occurring in walnuts (Kazakh varieties) under different storage temperature conditions was studied.

Thin-shelled walnuts with a high fat content, grown in the southern regions, were chosen as a model object for the study. The characteristics of biochemical indicators of walnuts, affecting the formation of organoleptic quality indicators and the nature of hydrolytic oxidative processes, were studied.

Walnut samples were processed and organoleptic, physico-chemical, microbiological indicators and safety of walnuts (Kazakh varieties) were studied before and after ozone treatment.

3 types of walnuts were selected (from Turkestan and Zhambyl regions) and quality and safety indicators were studied before and after ozone treatment.

The study showed that ozone treatment reduces and destroys the number of pathogenic microorganisms (total microbial number, mass fraction of moldy nuts, etc.), which contribute to a reduction in the shelf life of walnuts. At the same time, organoleptic (appearance of the shell and kernel, smell, taste, etc.) and physicochemical (mass fraction of moisture, mass fraction of nuts with defects in the appearance of the shell, etc.) indicators are improved.

Members of the project research team:

1 Scientific supervisor: Yakiyaeva Madina Asatullaevna, PhD, associate professor, postdoctoral fellow, yamadina88@mail.ru, https://is.ncste.kz/profile/15779, H-index – 7, Author ID in Scopus 57191979219, Researcher ID Web of Science AAL-7432-2020, ORCID ID 0000-0002-8564-2912

2 Scientific consultant: Iztaev Auelbek Iztaevich, Doctor of Technical Sciences, Professor, Academician of the National Academy of Sciences of the Republic of Kazakhstan, auelbekking@mail.ru, H-index – 7, Scopus Author ID 57204950041, ORCID ID 0000-0002-7385-482X

Project topic: IRN AR19577363 Development of technology of functional extrusion foods using wild plants of Kazakhstan.

Relevance of the project

Extrusion processing of vegetable raw materials is an environmentally safe processing method, which allows to obtain combined products with a given nutritional value and functional properties. Considering that extrusion processing can be carried out at different modes, it can be successfully used for creating combined products, enriching them with protein, vitamins, microelements and functional additives. The short-term nature of the extrusion process makes it possible to preserve as much as possible the heat unstable elements (vitamins, proteins). Sterilization of raw materials in the extrusion process improves sanitary conditions and extends the shelf life of finished products and destroys the microflora which causes their deterioration.

The data accumulated in the field of nutrition science show that in modern conditions of human life it is impossible to adequately provide the body with all the nutritional and minor biologically active components necessary to maintain its vital functions through traditional nutrition. Alternative sources are needed, which include wild edible plants of various families characterized by a higher content of BAS.

Our country is rich in many medicinal plants, which occur both in wild and cultivated forms. There are about 18,000 species of wild plants in Kazakhstan. Rich plant resources of Kazakhstan open to researchers huge prospects and wide opportunities in terms of search of new BAS and creation of new functional products on their basis.

Wild plants, widely represented in the vast expanses of our country, are of great importance in the national economy and in human life. They are the richest sources of vitamins, carbohydrates, fats, proteins, organic acids (citric, malic acid, etc.), aromatic substances, antioxidants, in which the human body is in dire need.

However, the limited and contradictory scientific information about the chemical composition and functional and technological properties of wild-growing raw materials depending on growing conditions and other factors predetermines the need to study the quality, chemical composition and safety of wild-growing plants of Kazakhstan, in order to expand the raw material base and the possibility of their application in the technology of functional food products. There are no technological solutions on application of products of wild-growing raw materials processing in production of extrusion products on grain basis (bread, snacks, slices, chips).

In view of the above, research aimed at solving an important problem associated with the creation of qualitatively new food products enriched with biologically active components isolated from environmentally safe wild plants of Kazakhstan is relevant and has an important social and economic importance.

The aim of the project is to develop recipes and technologies of extrusion products on a grain basis (bread, snacks, slices, chips), enriched with products of processing of wild-growing raw materials to improve their food, biological value and microbiological safety.

Expected results. As a result of the project based on the analysis of the chemical composition, functional and technological properties of wild-growing plants of Kazakhstan will substantiate the feasibility and effectiveness of the use of products safe for human health processing of wild-growing raw materials in the technology of extrusion products, developed recipes and technologies of extrusion food products on a grain basis (bread, snacks, slices, chips) using products of processing of wild-growing raw materials, as well as published 3 articles in peer-reviewed scientific journals on the scientific direction of the project, indexed in the Science Citation Index Expanded database Web of Science and (or) having the percentile on CiteScore in the database Scopus at least 35 (thirty-five), 3 articles in peer-reviewed foreign and domestic editions recommended by CQASHE, 1 monograph, filed 2 applications for a patent of RK.

Achieved results:

During the 1st year of the project:

- 1 research paper - thesis published at an international conference.

For the 2nd year of the project:

- 1 article was submitted to the journal having CiteScore percentile in Scopus database more than 35 (thirty five);

- 1 article was published in the journal "Vestnik ATU" (recommended by CQASHE).

Members of the research group of the project:

Izembayeva Assel Kamalseitovna, Hirsch Index:2, ORCID: https://orcid.org/0000-0002-1246-2726 , Scopus Author ID:57190159961

Moldakulova Zilikha Nurgalikyzy, ORCID: https://orcid.org/0000-0003-3098-1340

Atykhanova Makpal Baigaipovna, ORCID: https://orcid.org/0000-0002-1092-1853

Koylanov Kasymkhan Sansyzbayuly ORCID: https://orcid.org/0000-0003-2419-0788

Abdreeva Asemgul, ORCID: https://orcid.org/0000-0002-35678028

Ahlan Togzhan Bakytkyzyzy, ORCID: https://orcid.org/0000-0002-7883-7228

Askarbekov Eric Birlikovich ORCID: https://orcid.org/0000-0002-9544-0820

Figure 1 - Preparation of raw materials and extractant for extraction

Figure 2 - Conducting extraction

Translated with DeepL.com (free version)List of publications on the project:

Izembaeva A.K., Iskakova G.K., Bayysbaeva M.P.

Moldakulova Z.N.; The use of plant components in the production of excruciating products; Materials of the international scientific-practical conference "Innovative development of food, light industry and hospitality industry", October 26, 2023 ATU, Almaty, 2023. - С.70-71. file:///C:/Users/User%20B/Downloads/CamScanner%2003.11.2023%2012.36%20(2).pdf