The Department of Automation and Robotics is located in building 2-B in room 426.

The department has 5 computer rooms for conducting classes in engineering computer graphics:

The department has 5 laboratory rooms and 3 classrooms for lectures and practical classes, including:

Standard set of educational equipment "Instrumentation and automation", computer bench version, instrumentation and automation-SK

Specifications:

The laboratory stand is intended for training students of various specialties of secondary specialized and higher educational institutions studying disciplines related to the study of information collection tools and programming of industrial automation equipment.

Standard set of educational equipment “Fundamentals of Strength of Materials” OSM-11LR-11

The stand is designed for carrying out 11 laboratory works by a group of 2–4 people. In the basic configuration, the training complex consists of: a passport, an instruction manual and a manual for performing laboratory work.

The stand provides 11 laboratory works:

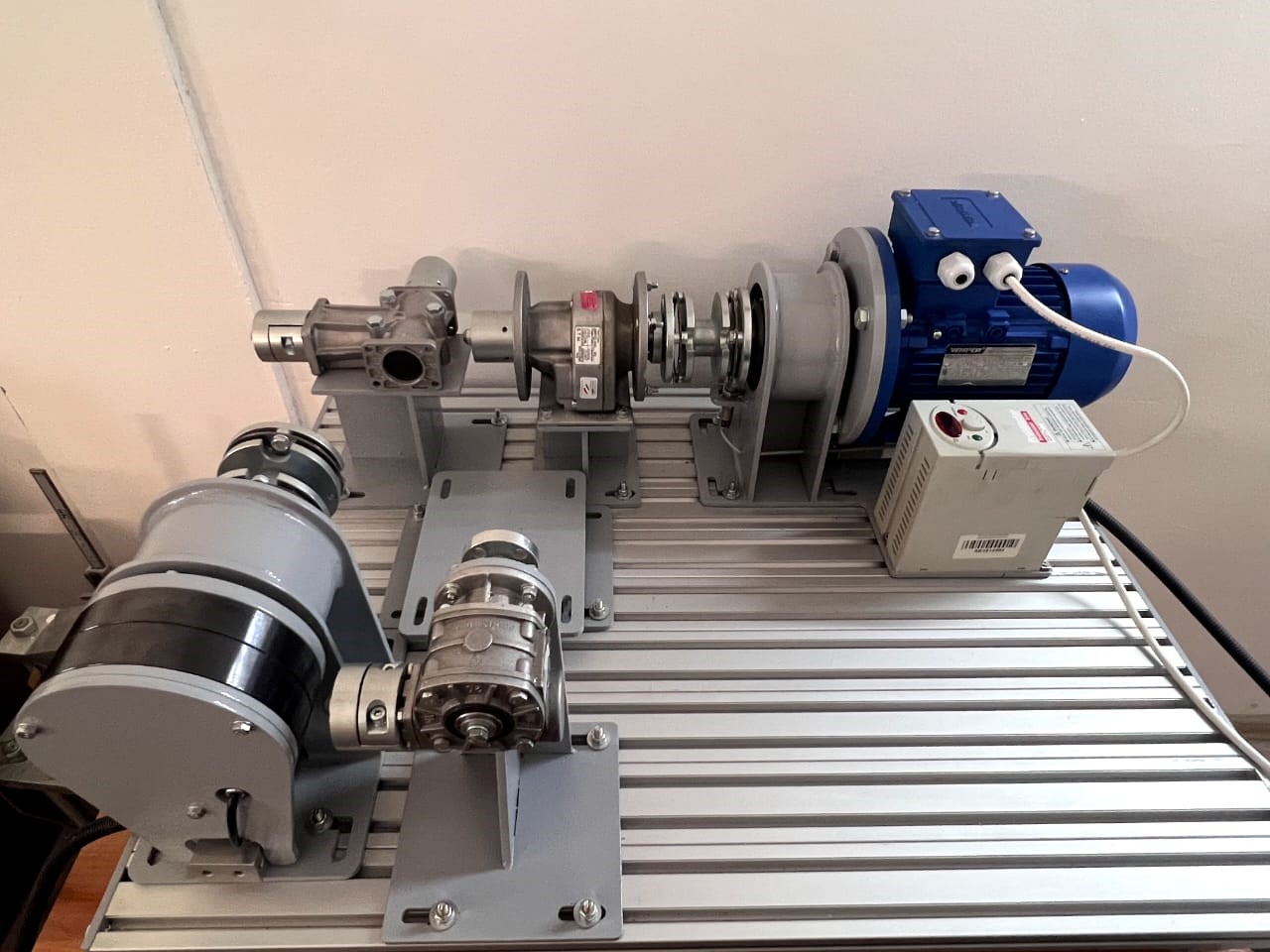

Automated laboratory complex «Machine parts - gear transmissions» (modular)

Specifications:

Laboratory works:

Standard set of training equipment “Pneumatic drive of food processing equipment” SPU-UN-PO-013-17LR

A standard set of educational equipment “Pneumatic drive of food processing equipment” SPU-UN-PO-013-17LR allows you to assemble various pneumatic systems to study the rules of their construction, operation and design.

Laboratory works:

Robotic training complex based on the industrial robot KUKA KR 6

The robotic educational complex based on the KUKA KR 6 robot is designed to train students in modern methods and technologies for using industrial robots in applied tasks, such as automatic welding and plasma cutting of metal structures, as well as to demonstrate other capabilities of industrial robots.

In the basic configuration, the training complex consists of:

The user interface of the KUKA system software is called KUKA smartHMI (smart Human-Machine Interface).